When maintaining the piggability of main lines was crucial, an elegant tie-in solution WAS necessary.

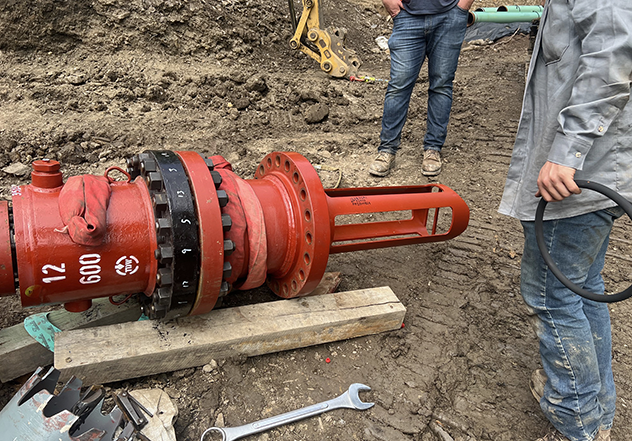

The job site with the two 12-inch x 12-inch 3-WAY™ Tee Fittings

Project Overview

A new natural gas well was being completed near Pittsburgh, necessitating the connection of two 12-inch lines from the well site to two 12-inch main lines. The 12-inch main lines needed to remain piggable.

Design & IMPLEMENTATION

To meet these requirements, an innovative solution using TDW 12-inch x 12-inch 600 class 3-WAY™ Tee Fittings with LOCK-O-RING® and pig guide bars was used. The LOCK-O-RING® completion plug features an interlock system that helps eliminate potential leak paths and ensures proper seating. The implementation process included:

Fitting Installation: The 3-WAY™ Tee Fittings were welded onto the 12-inch main lines.

Pipeline Connection: The 12-inch pipes with valves were welded to the 12-inch outlets on the fittings.

Hot Tapping: TDW service technicians performed two 12-inch Hot Taps.

Completion Plug Setting: The completion plugs with pig guide bars were set into the fittings by the TDW service technicians.

One of the completion plugs with pig guide bars

This approach allowed for the seamless integration of the new well site while maintaining the piggability of the main lines. By utilizing TDW's advanced fitting and plug technology, the tie-in solution not only met the immediate operational needs but also provided long-term reliability and safety for the pipeline system.

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy two years later, the company remains a family business serving customers with the highest quality service and expertise.

Our application specialists at Kerr Engineered Sales Company are also available for demonstrations, team presentations, lunch and learns and customer visits.